implementation in an on-farm biocircular perspective from the growth through to an on-farm delivery and off-farm use of raw sugers and protein juice

Adapted to beet, sugar cane or sweet sorghum at minimum transport and energy use

Building upon the usual harvest procedures, the biomass is mashed and pumped into a lagoon or circular container where the additive is added and process controlled.

In a livestock perspective per se

On dairy farms, pig operations and biogas plants

Leading to a pumpable home-grown next-to-full feed which is, rich in sugers and proteins, at zero fermentation losses, of improved digestibility and liquidity.

Livestock

In a feed and bioeconomy perspective

ON-FARM DELIVERY FOR OFF-FARM INDUSTRIAL PURPOSES

Required is a daily on-Farm separation of the biomass mash into a solids (waste) fraction for Milk, Meat or Biogas and an upgraded sugar and protein juice for temporarily storage in a cylindrical tank until the delivery hereof to the end-user.

Total seperation of the biomass into feed (waste) and juice

On-farm scenarios

Screw press seperation plant

Screw press

Waste (feed)

Stationary on-farm beet wash and shoop equiptment

Juice

Pumbable beet mash

The production af feed and biogas on waste meets the political ambitions of reducing the acreage for production of Feed and Biogas in favour of acreage devoted to Food at improved local prosperity

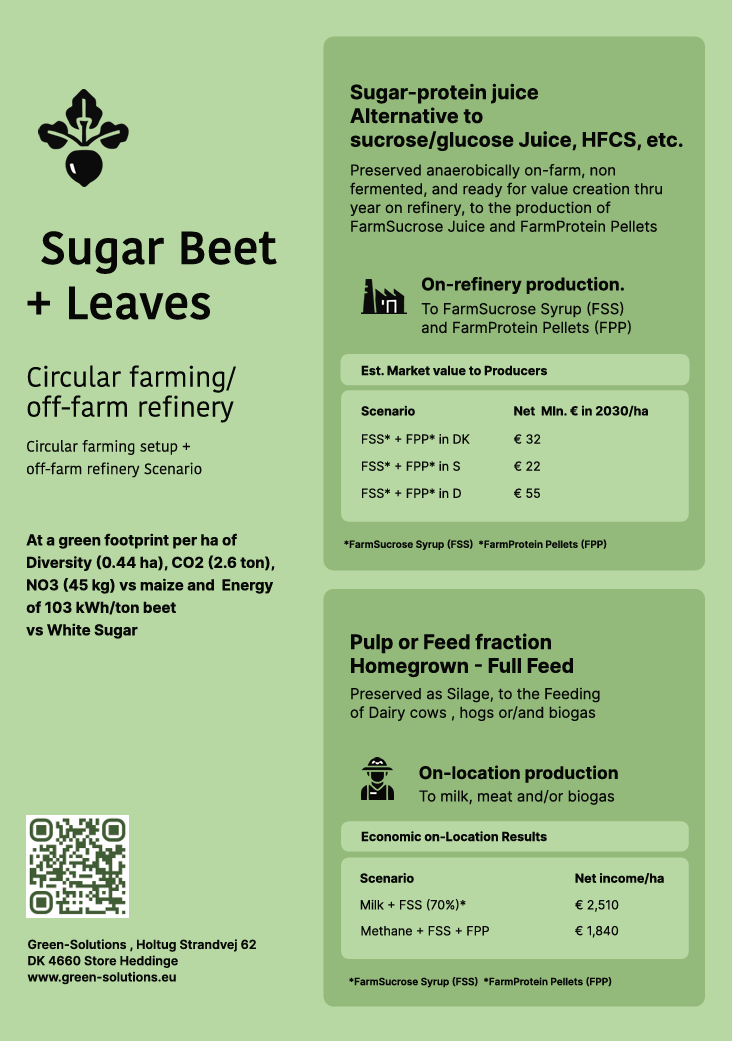

Economical and Environmental benefits at the implementation model Scenario 3A

Abstract.

This report presents a patented process technology designed to stabilize sugar and protein compounds in whole-crop sugar beet biomass through anaerobic storage. By preventing fermentation at both small and large scale, the technology enables decentralized production of two high-value biobased products: FarmSucrose Syrup (FSS) and FarmProtein Pellets (FPP). This innovation unlocks new value streams in

agriculture while reducing environmental impact. The business model is demonstrated through Scenario 3A, involving a platform of 30 farms (see poster below). Each farm performs on-site juicing and storage, with downstream upgrading at a centralized facility. The remaining beet and leaf pulp are retained for milk or methane production, creating an integrated and circular system. Scenario 3A has been financially modelled using conservative yield and pricing assumptions. Results show positive net returns per hectare in both dairy and biogas pathways—without reliance on state subsidies. The model captures multiple revenue streams while reducing input costs, offering an attractive risk-return profile at farm and portfolio level. Patents are secured in Europe, the U.S., and Eurasia, with scalability potential across sugar beet-producing regions, particularly in Northern and Eastern Europe. In terms of impact, Scenario 3A:

Lowers energy use by >100 kWh/ton vs. conventional sugar production

Frees up 0.43–0.46 ha per hectare for biodiversity or carbon projects

Reduces nitrate leaching and import dependence on soy protein

Converts climate policy into tangible farm-level value

This report offers a proof-of-concept for a commercially scalable, climate-aligned agri-tech solution with strong IP, solid unit economics, and multiple market applications.

Confidential report

The full Economy–Environment Report can be made available for professional review upon request, under appropriate confidentiality.

From seed to feed – one implementation scenario

One concrete implementation scenario – from seed in the soil via harvest, storage and processing to FarmSucrose Syrup and FarmProtein Pellets – has been worked out in detail. The poster below shows:

How the feed fraction is ensiled

How the juice fraction is stored under non-fermentation conditions

How this enables year-round on-farm production

What level of on-farm / biogas operational income can be expected under conservative estimates

How upscaling in DK, DE and SE by 2030 expands the potential for FarmSucrose Syrup and FarmProtein Pellets on the market.

Literature of relevance to the concept:

Deloitte (2014): “Opportunities for the fermentation-based chemical industry”

Analyse af fermentationsbaseret kemi i Nordeuropa. Påpeger, at tynd/tok saft fra sukkerroer kan erstatte energikrævende hvidsukkerproduktion og øge ressourceeffektiviteten.

https://www.deloitte.com/lk/en/Industries/retail/research/opportunities-for-fermentation-based-chemical-industry.html

Hedegaard et al. (2014): “Røer tilbage i dansk landbrug – potentiale i ny kombination af foder og bioenergi” (FOBIO)

Detaljeret analyse af roer og bladmasse. Dokumenterer lagringsproblemer ved gæring i biomasse — et teknisk hovedproblem FarmSucrose adresserer.

https://pure.au.dk/ws/files/37055491/Samlet_rapport_FOBIO.pdf

Bannink et al. (2025): “Methaan reduceren: van ongrijpbaar probleem naar kans voor de boer”

Viser, at metanreduktion via rationstilpasning både er muligt og økonomisk fordelagtigt. Attentiemail Rundveehouderij - WUR. https://www.wur.nl/nl/onderzoek-resultaten/onderzoeksinstituten/livestock-research/nieuws-en-agenda/attentiemail-rundveehouderij.htm

Kleinhout (1990): “The use of Fodder Beet as a Whole Crop”

Indeholder første faglige beskrivelse af vigtigheden af at bevare sukkerfraktionen i ensilage — et princip centralt for FarmSucrose.

Milk and meat from forage crops : proceedings of a conference held at Peebles, Scotland 21-23 February 1990 - Portland State University (p 157-172)

Kleinhout (1984): “Stopft Futterlücken: Stroh plus Rübenblatt”

Praktisk artikel om foderværdi og rationoptimering med roeblade og halm.

Kleinhout (1983): “Futterwert der Mais-Rüben-Silage wird ganz erheblich unterschätzt”

Tidlig dokumentation for højt energi